Molding and casting

individual assignment:

design a mold around the stock and tooling that you'll be using, mill it (rough cut + (at least) three-axis finish cut), and use it to cast parts

This week I decided to make a chess piece and choose my favorite piece, which is the minister

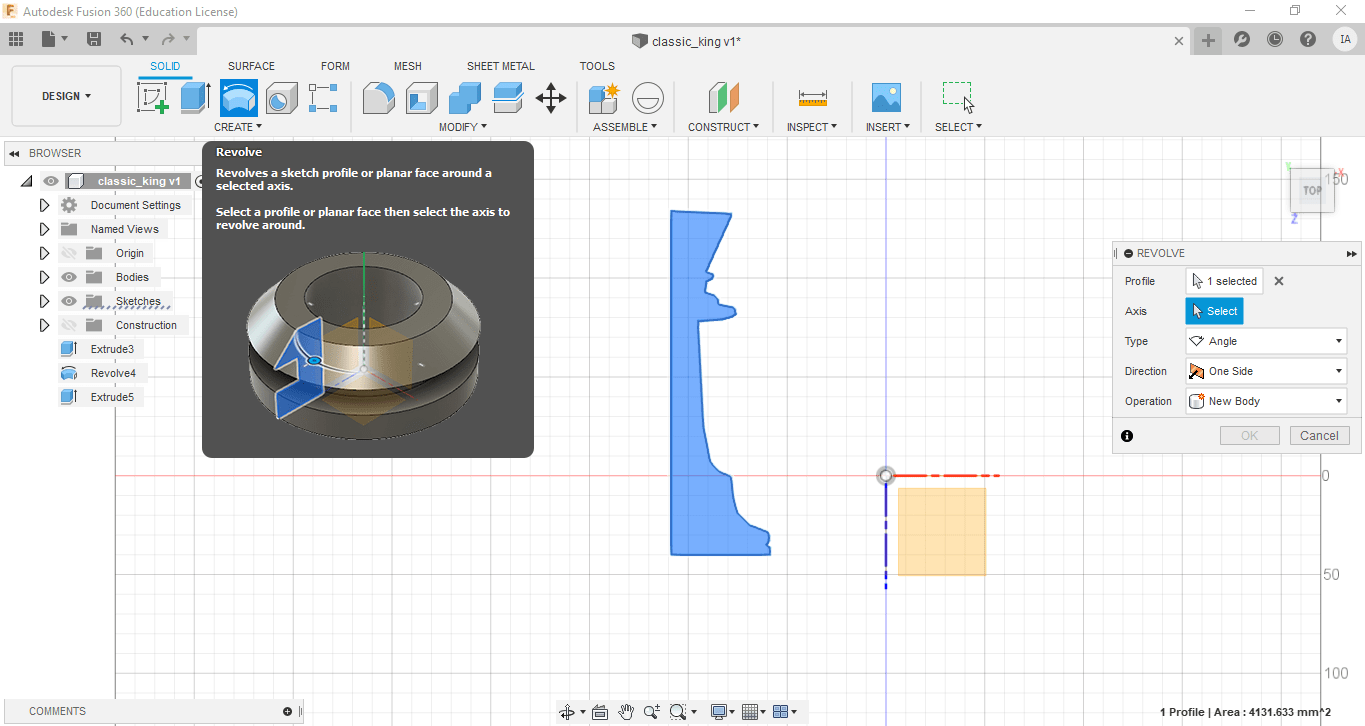

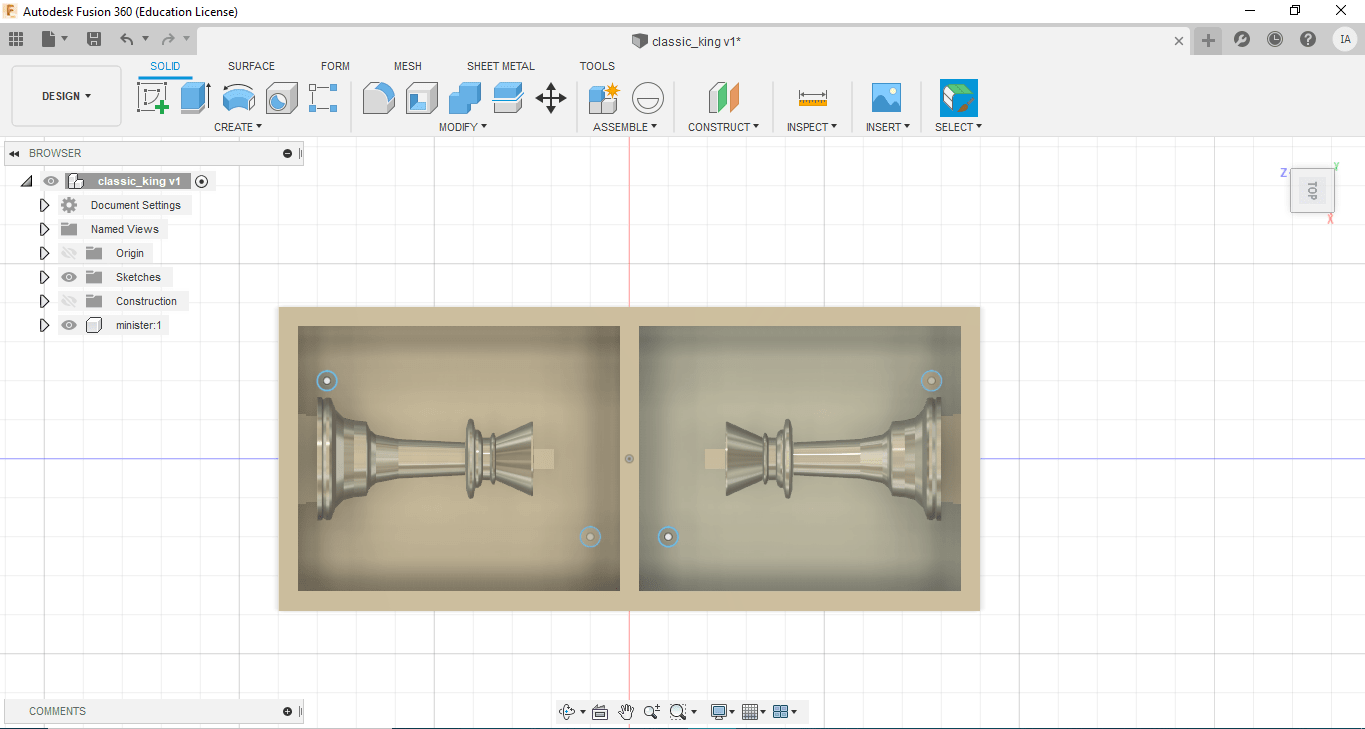

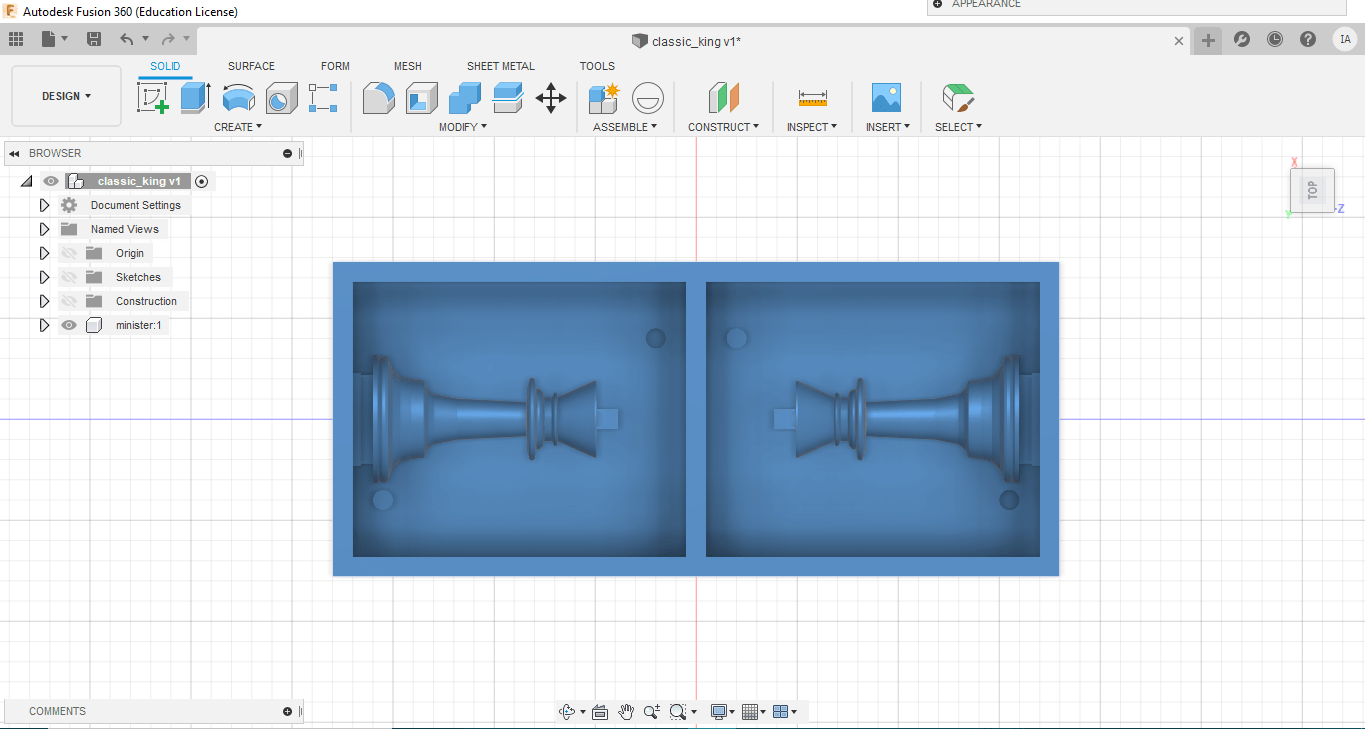

Beginning of drawing a chess piece using Fusion 360

Beginning of drawing a chess piece using Fusion 360 First I drew the two-dimensional minister, then use the Revolve command

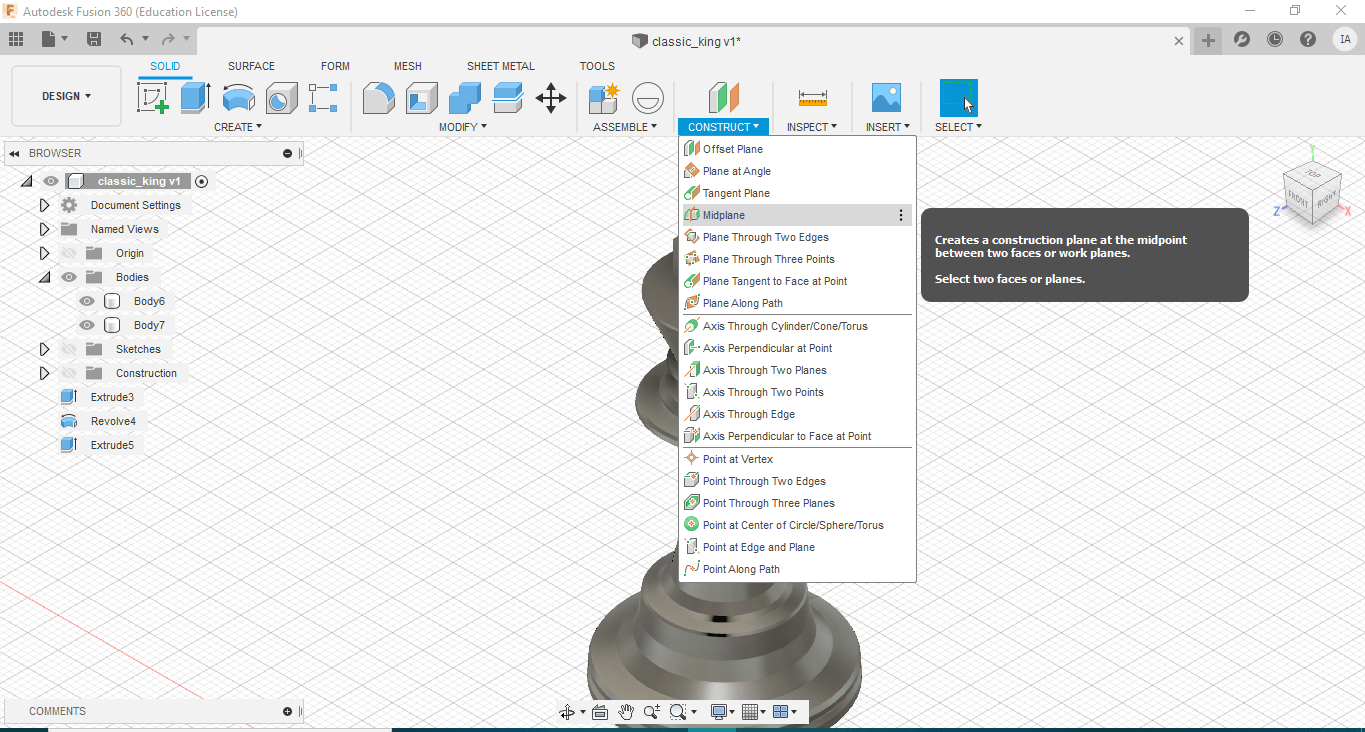

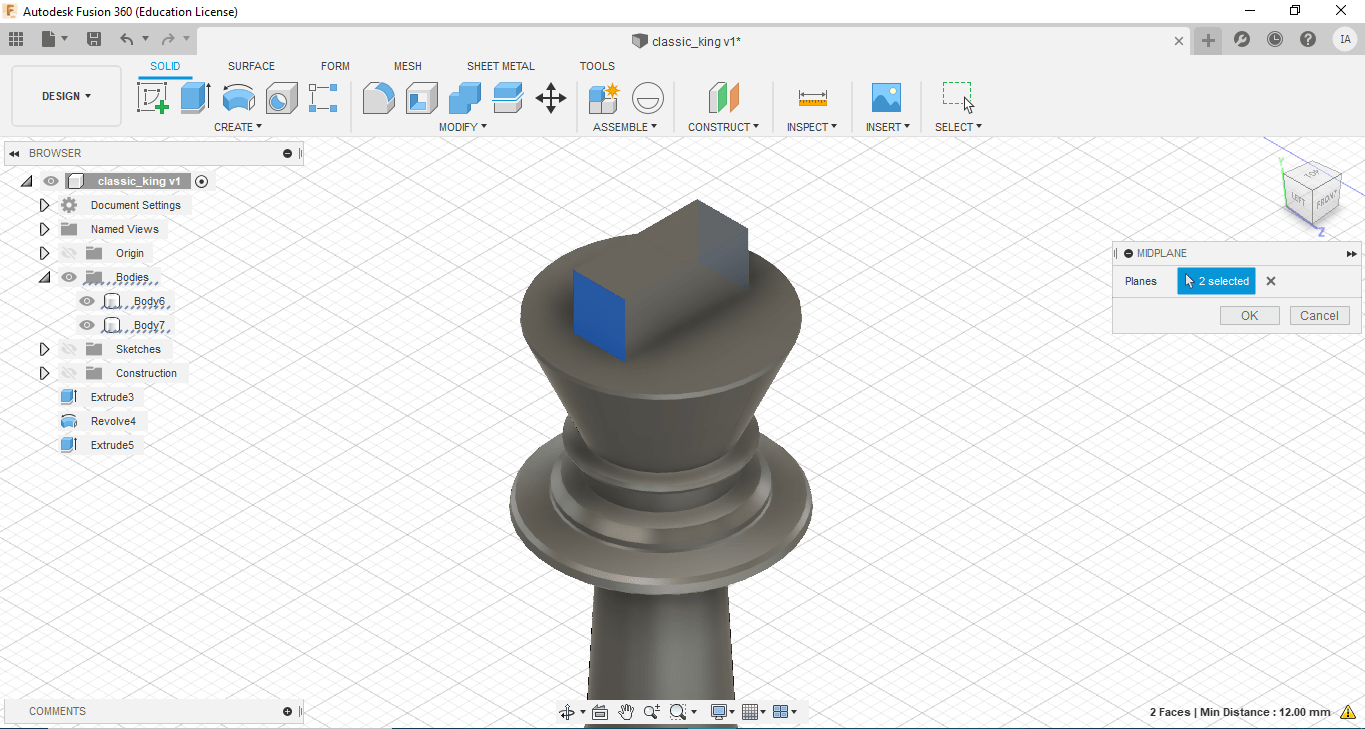

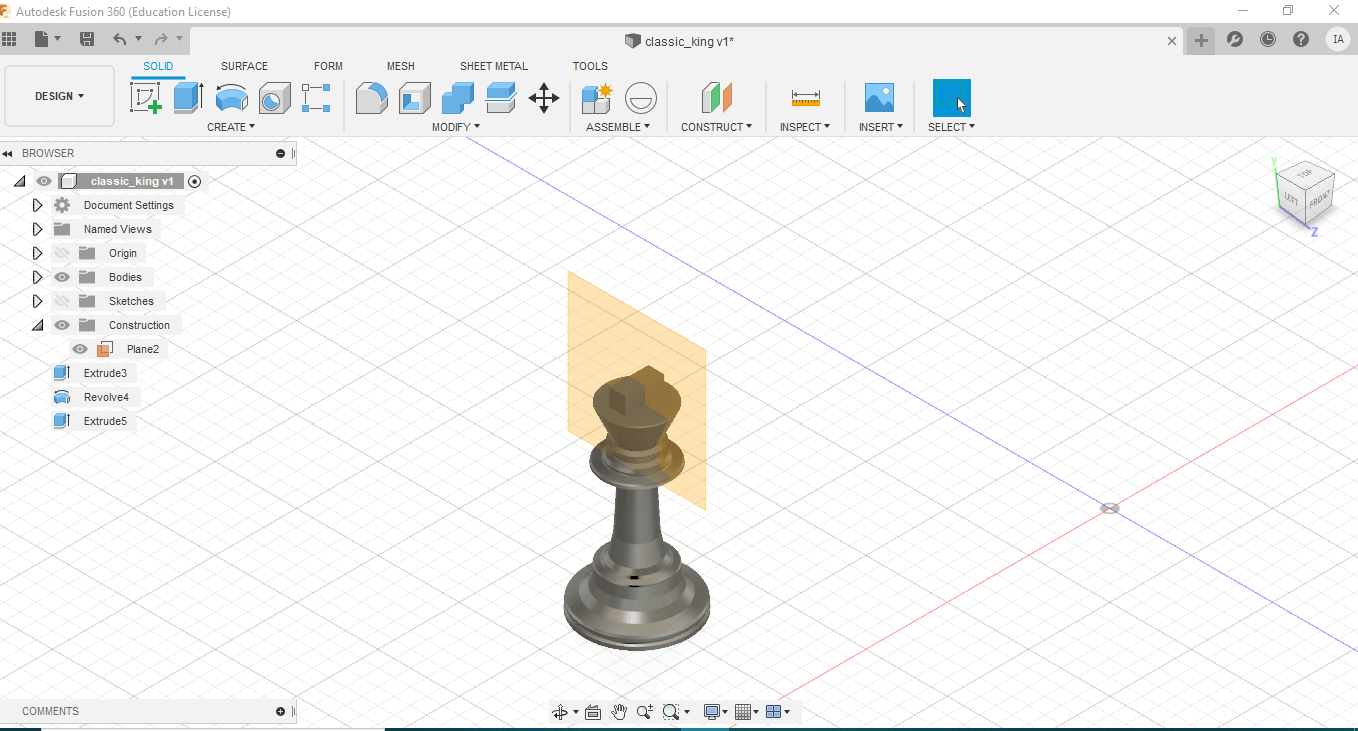

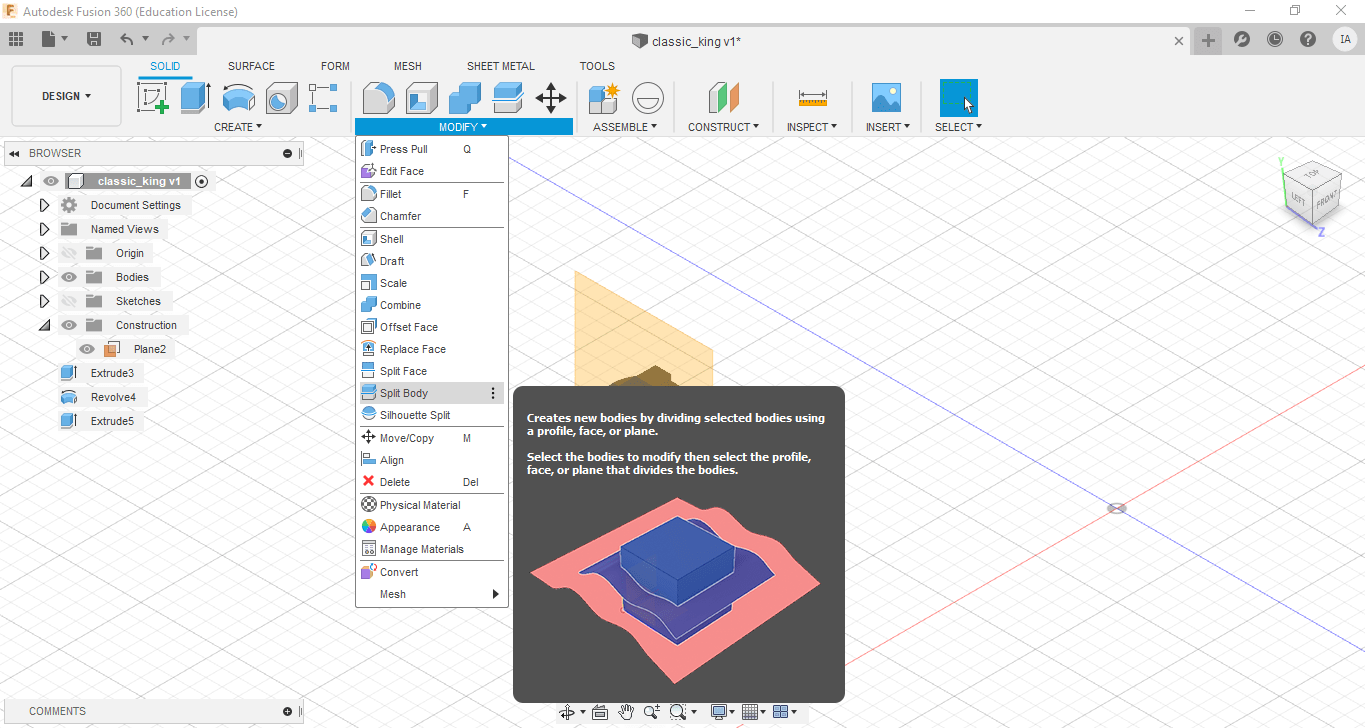

Now that a plant has been created in the middle through a modification command, choose the Split Body command for the stone section

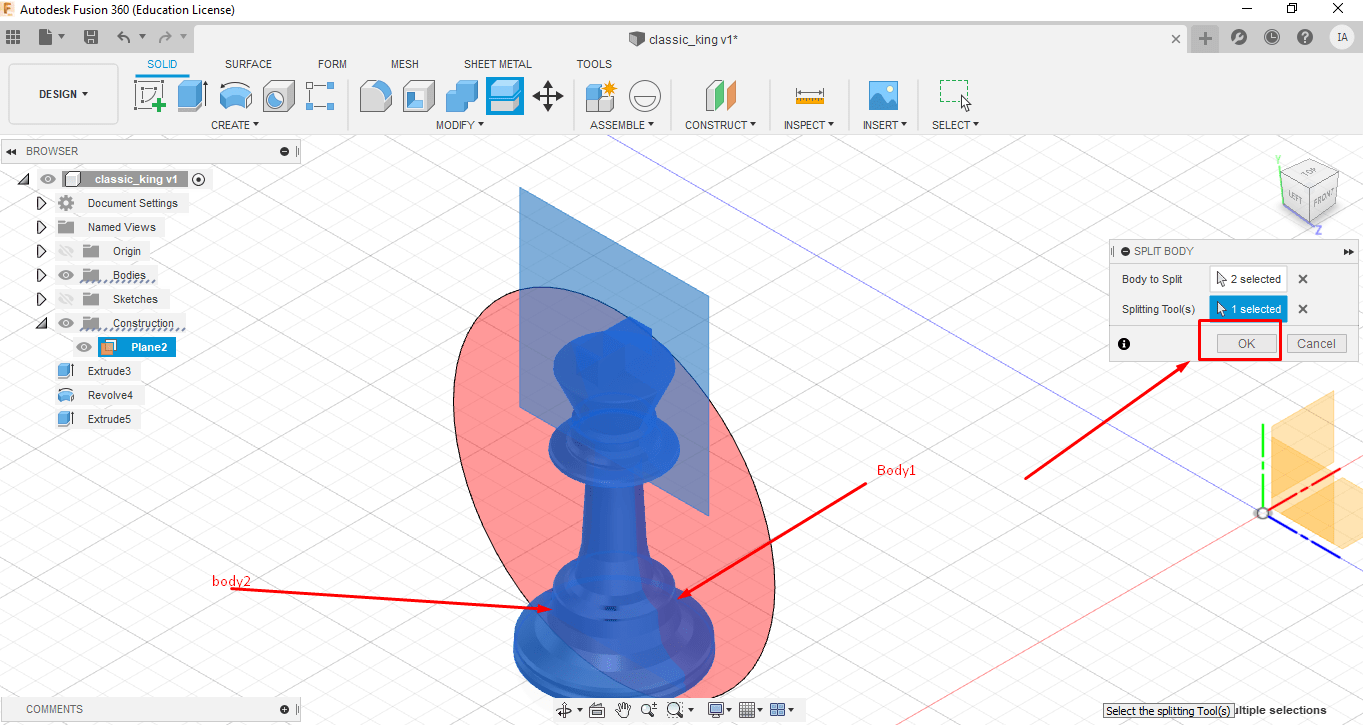

Select the two symmetrical ends of the stone to be divided by the middle

Now that a plant has been created in the middle through a modification command, choose the Split Body command for the stone section

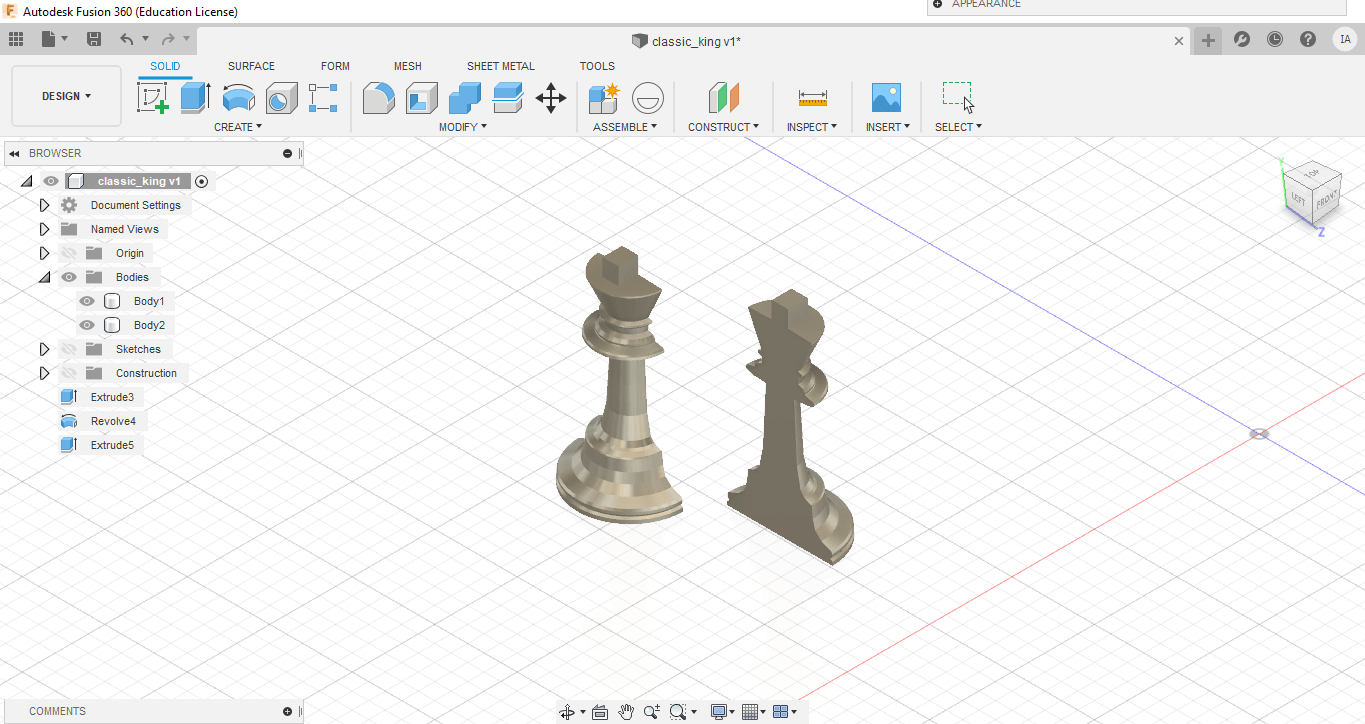

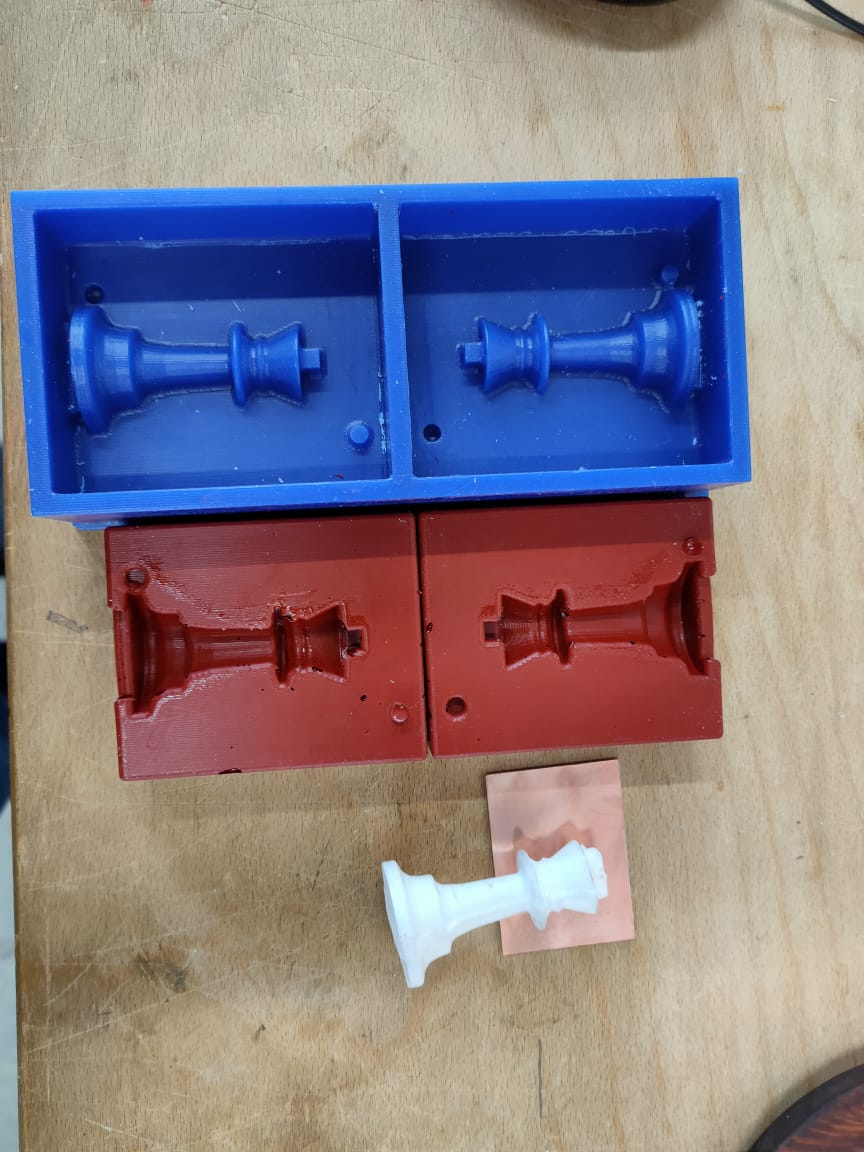

Thus, I have two bodies

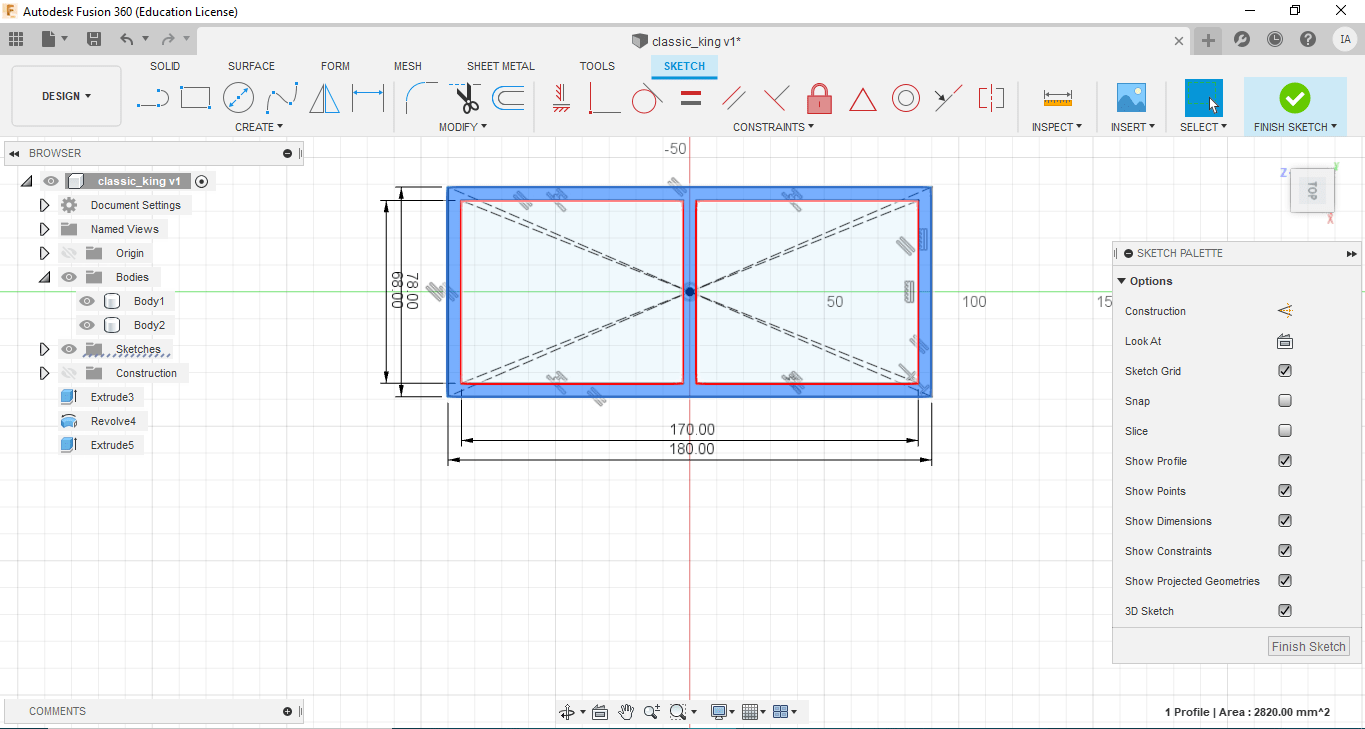

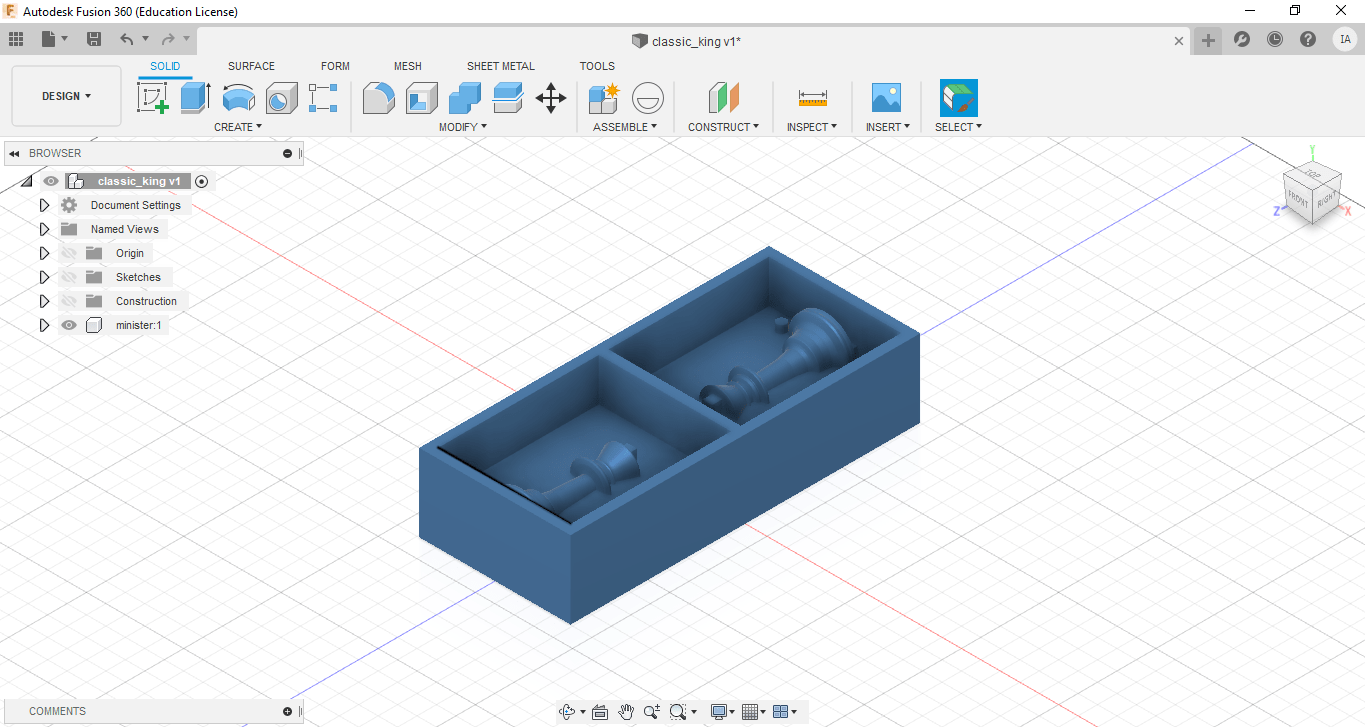

And now I am making the template for my design with the sizes shown in the picture

After that I make the mounting screws inside the design

So my design is ready and I export it in stl format

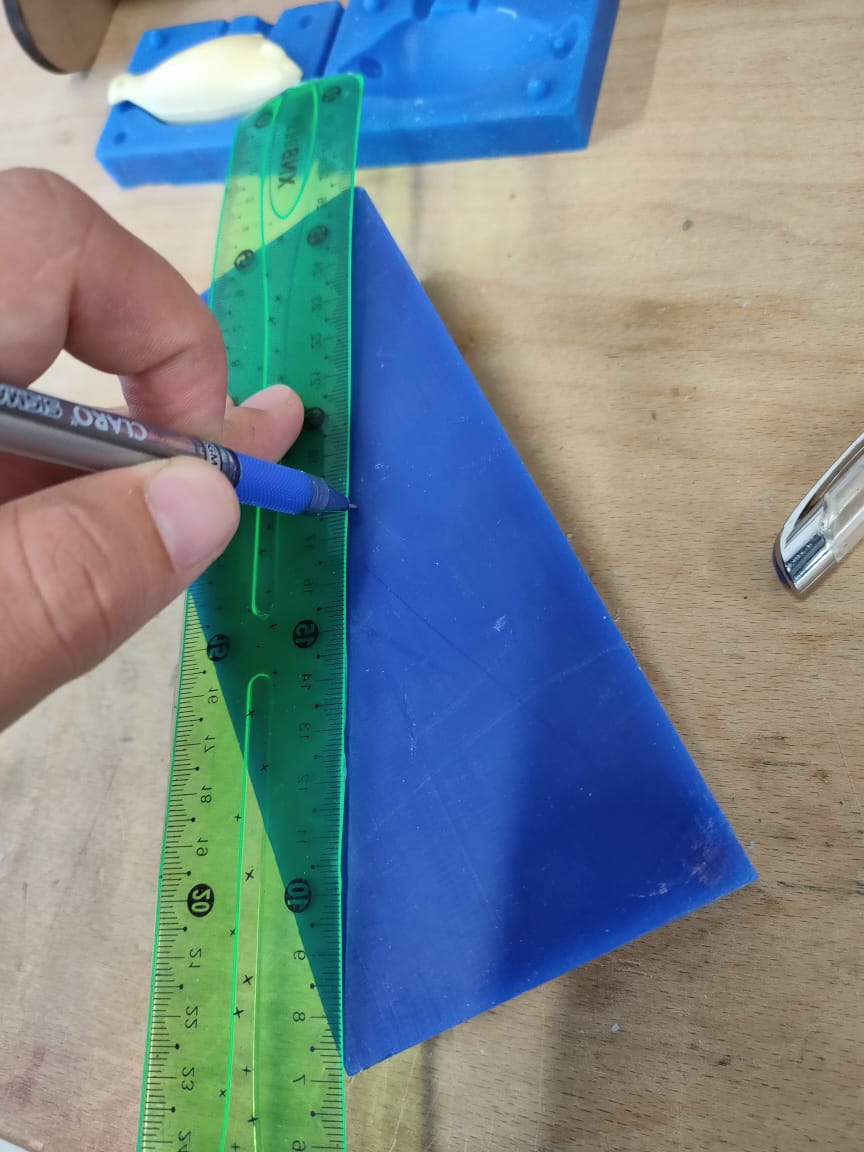

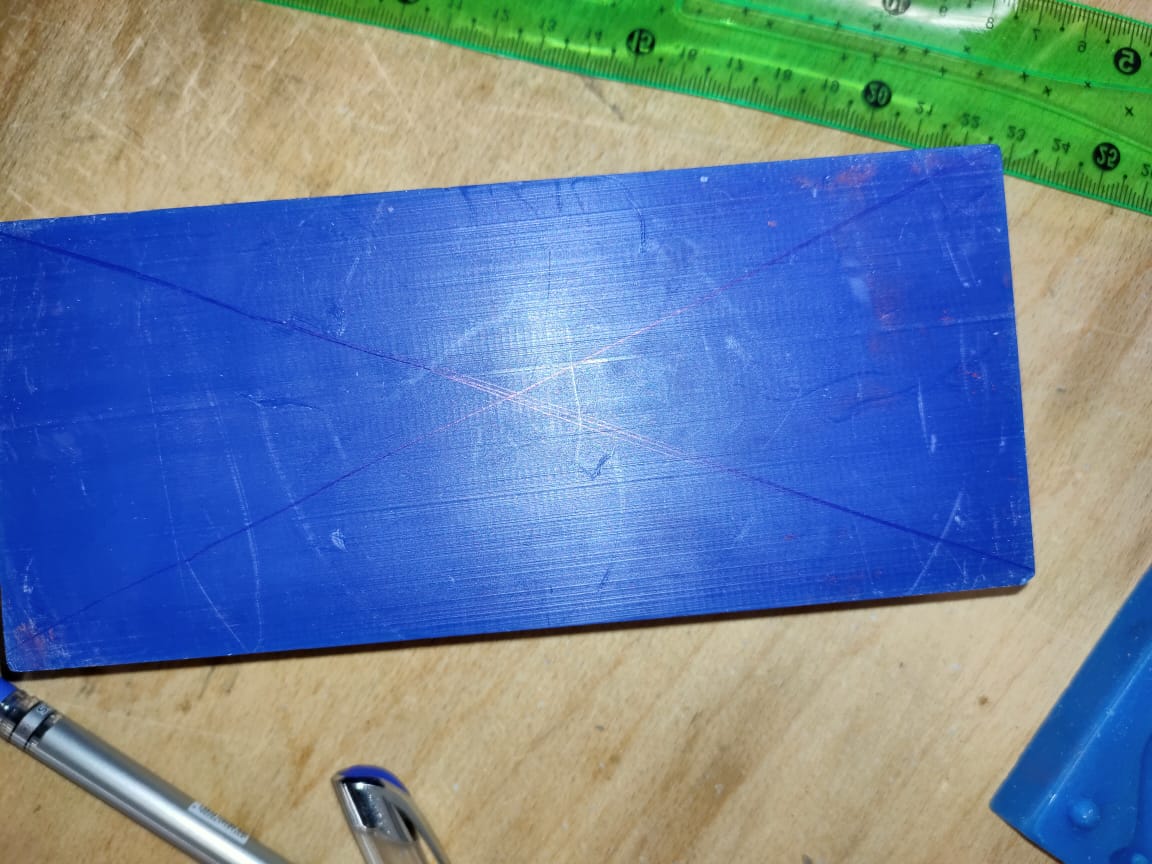

I am drawing two diagonals marking the midpoint to set the z axis

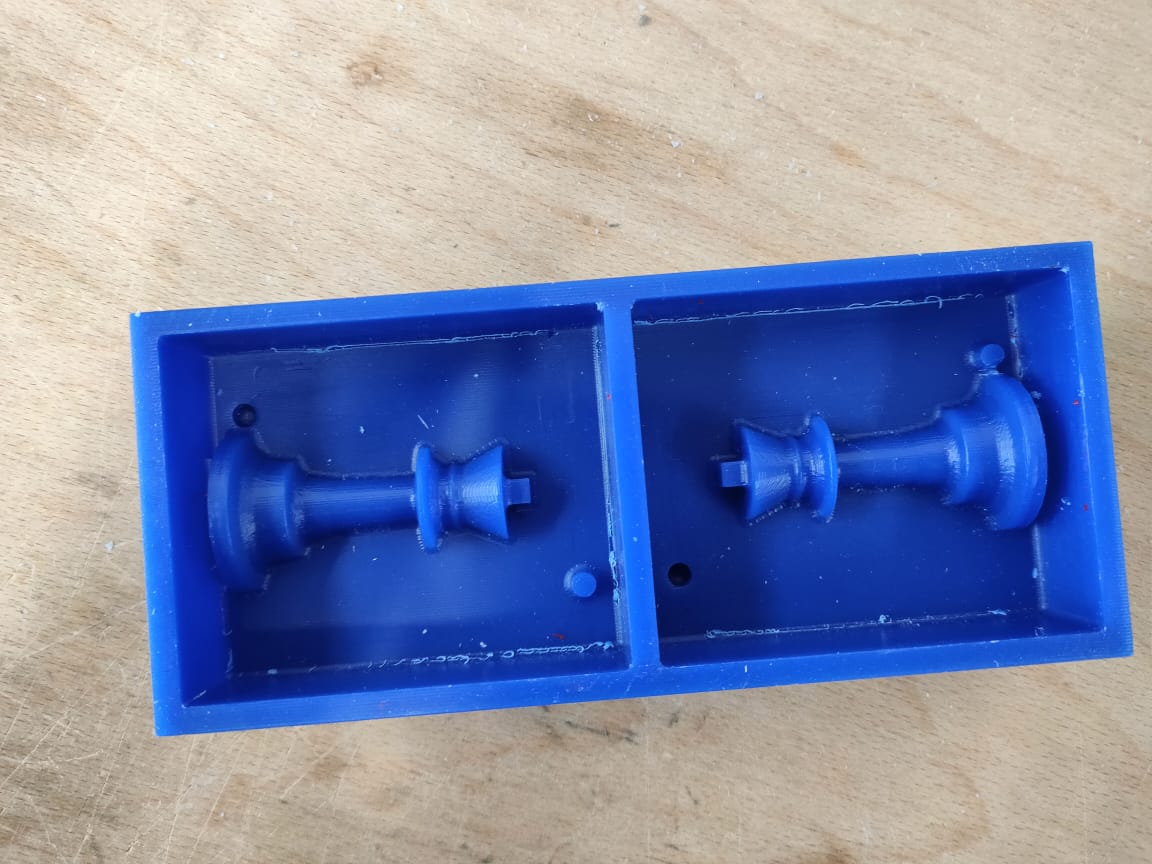

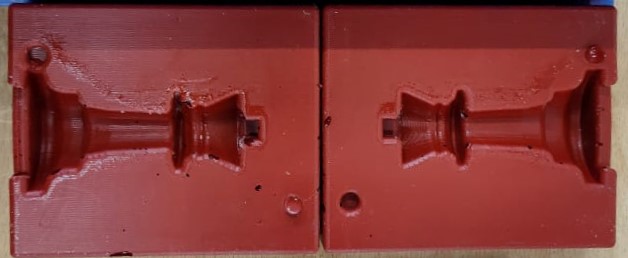

This is the final shape after I have finished digging

After that I filled it with water and poured it with a cup to find out the weight of the whole substance

First, I zeroed the weight of the cup

Important; you must weigh Part A & B components using a gram scale to be successful with Mold Max™ 60 As the mixing ratio is 100 A: 3b

This is the remote result of the cup after pouring it and leaving it for 24 hours to dry

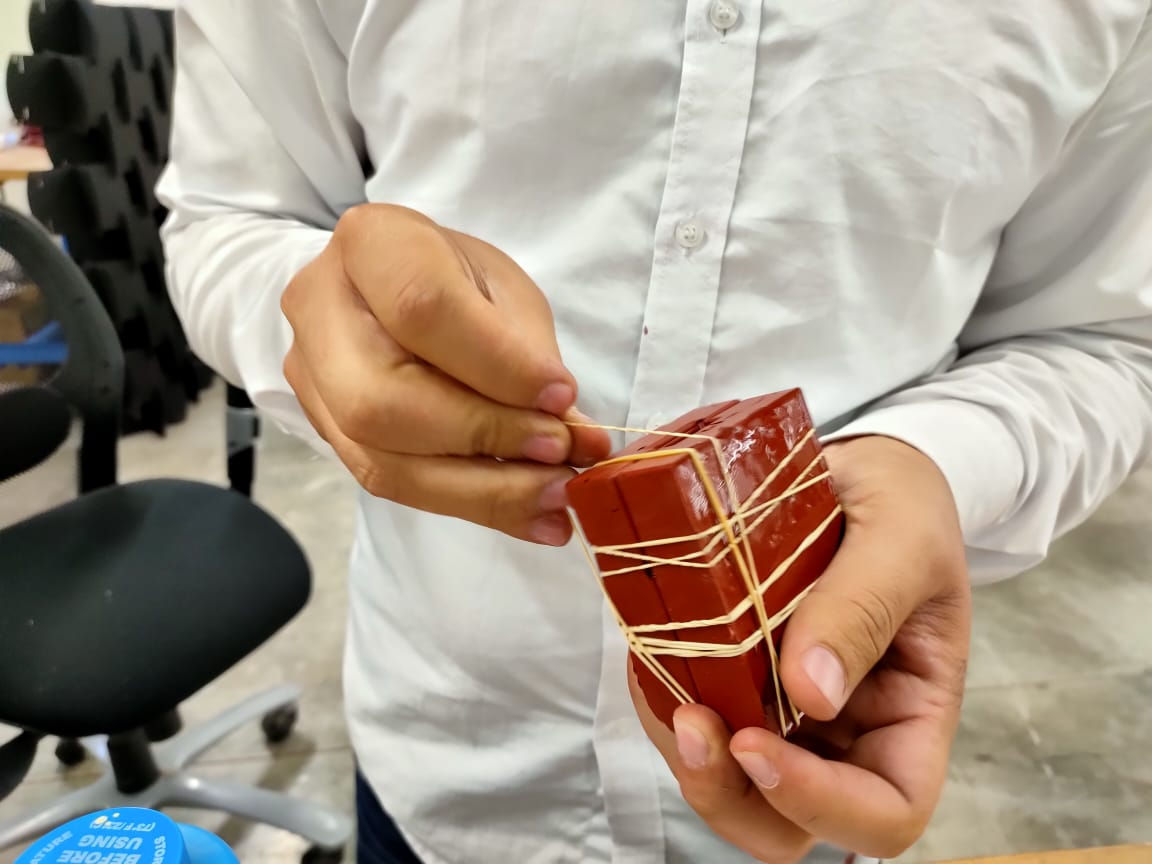

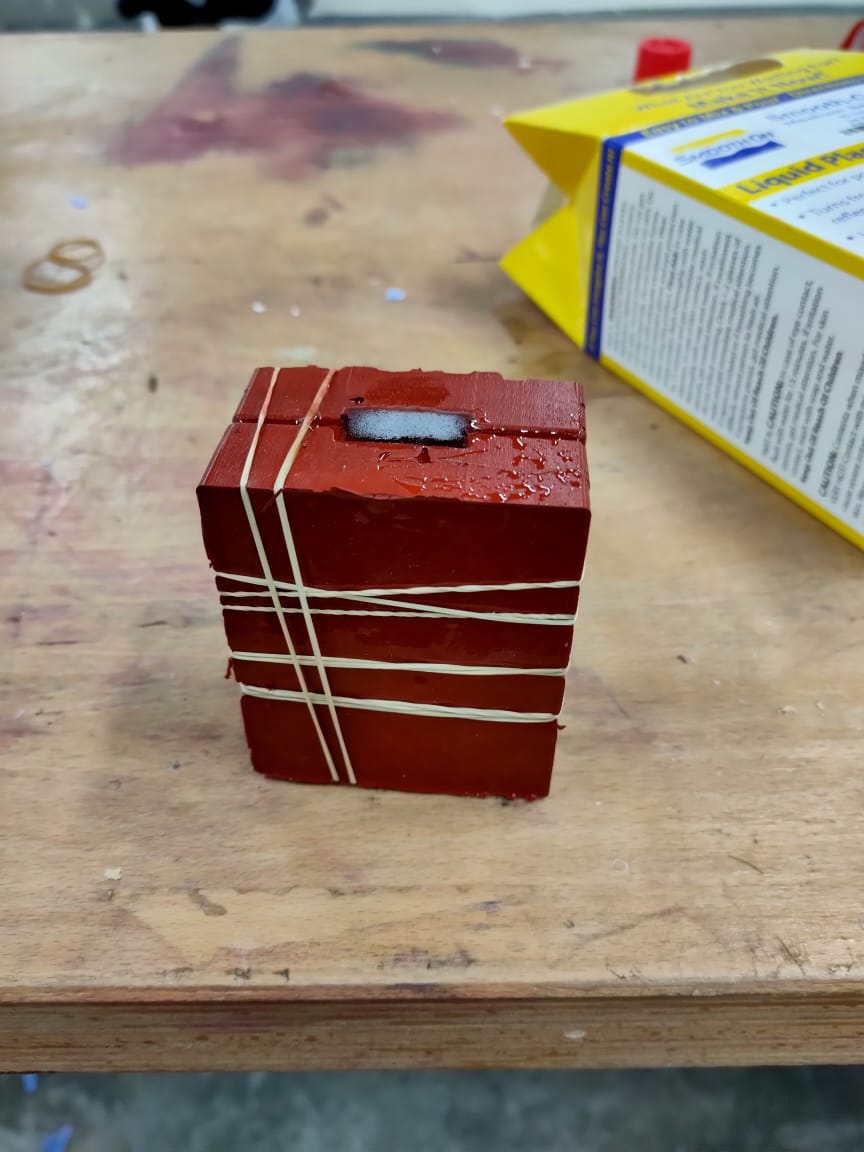

Now join both blocks together to form the template in which I will form my design

, I decided to use Mold Star 30 silicone rubber, And I made sure to clean the mold well and then mix the two materials A & B in a 1: 1 ratio as recommended in the data sheet

And this is the final result after the casting is finished

you can download my design click here